The spark gap automated test system (SGATS) is used to perform automated testing of gas-filled spark gaps. Spark gaps are high-energy, voltage-controlled switching devices, with the ability to switch currents of thousands of amperes. The SGATS can perform quality control testing for production units or life cycle testing. The system is capable of measuring extremely high voltages and currents and very high speeds. The pass-fail criteria are defined in the recipe configuration. The automated test controls the firing and measures of various voltages and currents. The analysis of the multiple waveforms captured during each firing determines the pass-fail status of that unit under test. The system can test up to 4 units at a time, automatically sequencing each active unit in the system during testing. CGM developed all the software and hardware used in the SGATS. The system is contained within a portable cart designed and built by CGM. The high-voltage switch used in this system was also designed and fabricated by CGM.

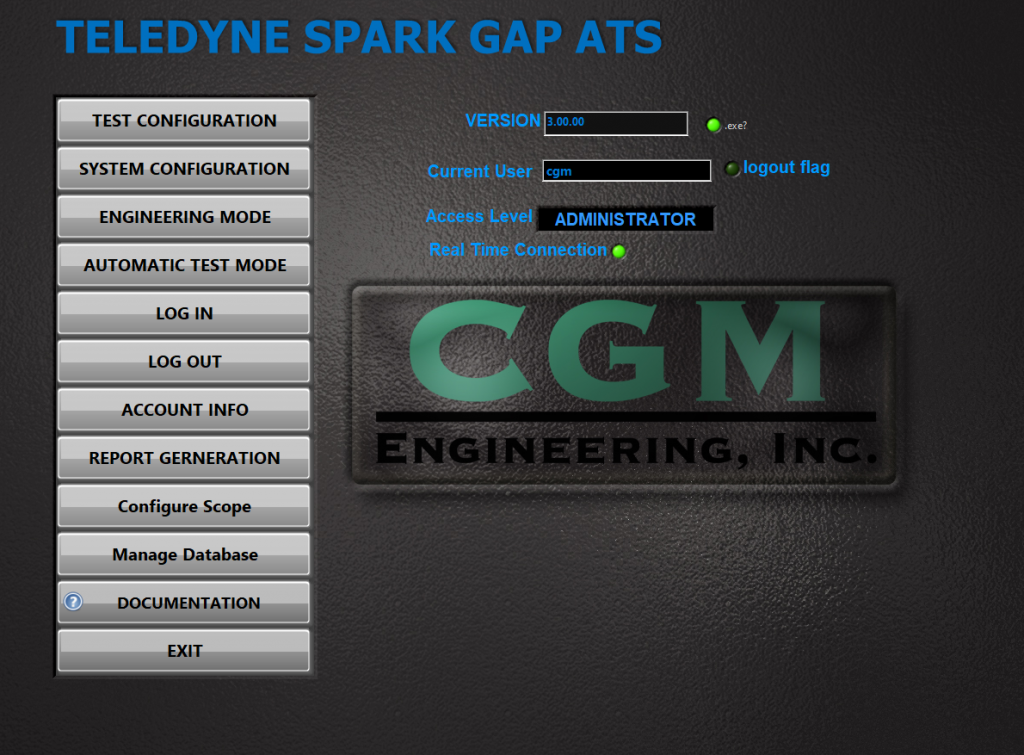

SGATS Software

The main menu

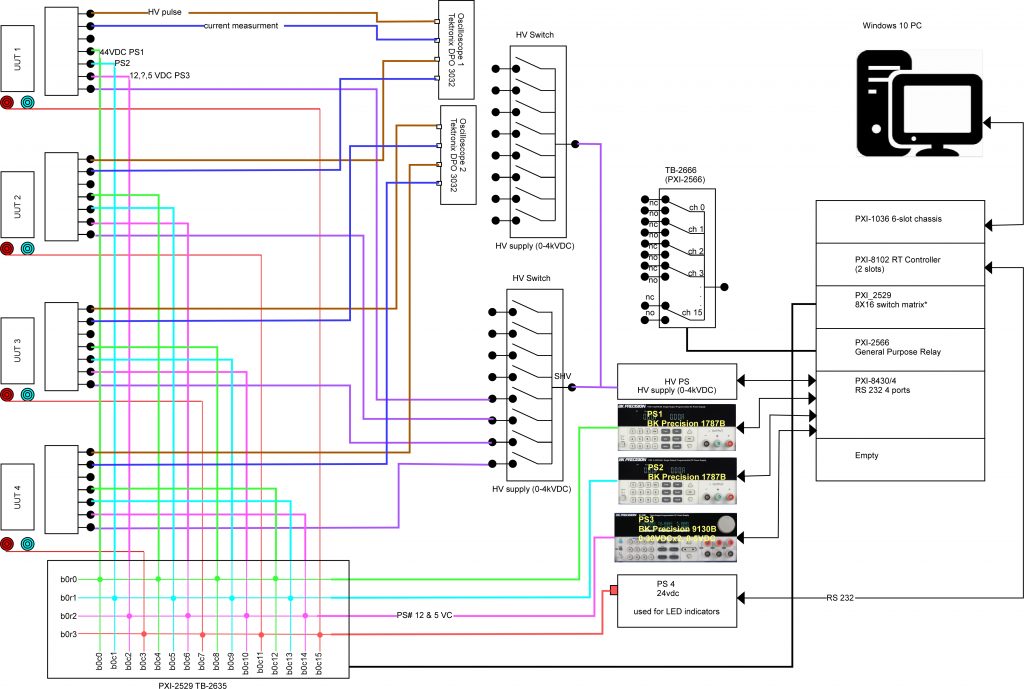

System Architecture

The system has 4 stations available for unit testing. Only one station is under test for each pulse step. Appropriate voltages required for each test pulse are routed to the designated station through a series of switches. Each station has dedicated connections to two oscilloscopes for three high-speed measurements. The oscilloscopes utilize calibrated trigger routing for synchronization of the acquisition.